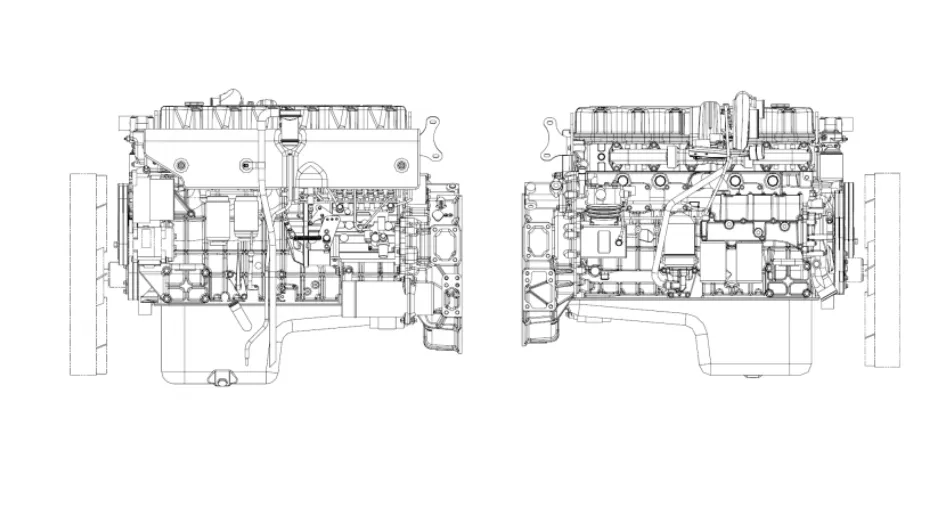

The FAW Engine Mounting system represents a critical component in the CA3250P66K2L1T1E 6×4 flat-head diesel dump truck, engineered to provide optimal vibration isolation and structural stability. This comprehensive guide breaks down the entire FAW Engine Mounting assembly into its smallest serviceable components, enabling maintenance professionals and parts specialists to identify, source, and replace individual elements with precision. The systematic disassembly approach detailed here ensures that both large structural members and complete procurement items are cataloged to their most fundamental repair units, facilitating efficient maintenance operations and reducing downtime for heavy-duty vehicles.

Understanding the intricate design of the FAW Engine Mounting system is essential for proper vehicle maintenance and longevity. Each component within this assembly plays a vital role in distributing engine loads, minimizing operational stress, and maintaining alignment between the power plant and chassis. The decomposition methodology presented here follows factory specifications and engineering guidelines to ensure accuracy in parts identification and compatibility.

The FAW Engine Mounting system in the CA3250P66K2L1T1E model incorporates advanced vibration damping technology specifically designed for heavy-duty applications. This system consists of multiple mounting points that work in concert to absorb engine vibrations and shock loads during operation. The precision engineering of the FAW Engine Mounting ensures minimal transfer of vibrations to the vehicle chassis, thereby enhancing driver comfort and protecting sensitive vehicle components from excessive stress.

Each element within the FAW Engine Mounting assembly serves a distinct purpose. The front mounting system includes specially designed brackets and cushioning components that accommodate engine movement while maintaining precise alignment. The rear mounting configuration provides additional stability during acceleration, deceleration, and when navigating uneven terrain. This balanced approach to engine suspension is a hallmark of FAW’s engineering excellence in commercial vehicle design.

Regular inspection of the FAW Engine Mounting system is crucial for vehicle safety and performance. Wear indicators include visible cracks in rubber components, loose fasteners, metal-to-metal contact between components, and excessive engine movement. Preventive maintenance of the FAW Engine Mounting can significantly extend the service life of both the engine and transmission systems by ensuring proper alignment and reducing stress on connected components.

| Index | Part Number | Part Name | Quantity |

|---|---|---|---|

| 1 | Q18516140TS | Hexagon Head Flange Bolt | 2 |

| 2 | 1001031B50A | Left Front Mounting Bracket | 1 |

| 3 | Q1821250 | Hexagon Flange Bolt (R-Type) | 8 |

| 4 | 1001030-76A | Engine Front Mount Upper Cover Assembly | 2 |

| 5 | 1001025B50A | Engine Front Mounting Cushion Assembly | 2 |

| 6 | CQ1601060TS | Hexagon Head Bolt | 8 |

| 7 | 1001037B50A | Engine Front Mounting Bracket | 2 |

| 8 | CQ41910 | Tapered Elastic Washer | 8 |

| 9 | CQ34010 | Hexagon Nut | 8 |

| 10 | 1001028-76A | Lower Plate – Engine Front Mount | 2 |

| 11 | Q32916 | Type 1 Non-Metal Insert Hexagon Lock Nut | 2 |

| 12 | Q1841650TS | Hexagon Flange Bolt Thick Rod (Standard Type) | 8 |

| 13 | 1001065-50V | Rear Mounting Bracket Cushion Assembly | 2 |

| 14 | Q32918T | Type 1 Non-Metal Insert Hexagon Lock Nut | 2 |

| 15 | 1001079-263 | Base Plate – Rear Mount | 2 |

| 16 | 1001063-483 | Upper Plate – Engine | 2 |

| 17 | Q18518160T | Hexagon Flange Bolt (Standard Type) | 2 |

| 18 | 1001032B50A | Right Front Mounting Bracket | 1 |

Proper maintenance of the FAW Engine Mounting system begins with regular visual inspections. Technicians should examine all mounting components during routine service intervals, paying special attention to rubber elements that may show signs of cracking, hardening, or separation. Bolts and fasteners should be checked for proper torque specifications, as loose connections can lead to premature wear and potential failure of the entire FAW Engine Mounting assembly.

When replacing components within the FAW Engine Mounting system, it is crucial to use genuine parts that meet factory specifications. Aftermarket components may not provide the same vibration damping characteristics or durability, potentially compromising vehicle performance and safety. The comprehensive parts breakdown provided in this guide ensures that maintenance professionals can identify the exact components required for each repair scenario.

The design of the FAW Engine Mounting incorporates multiple failure points that can be individually addressed, significantly reducing repair costs compared to complete assembly replacement. This modular approach to engine suspension maintenance represents a significant advantage for fleet operators seeking to optimize maintenance budgets while ensuring vehicle reliability and operational safety.

The engineering behind the FAW Engine Mounting system focuses on achieving an optimal balance between vibration isolation and structural rigidity. Through extensive testing and refinement, FAW has developed mounting components that effectively dampen engine vibrations across a wide frequency range, contributing to enhanced driver comfort and reduced noise levels within the vehicle cabin. The sophisticated design of the FAW Engine Mounting also helps minimize stress transmission to adjacent components, extending their service life.

Under demanding operating conditions typical of dump truck applications, the FAW Engine Mounting system demonstrates exceptional durability. The materials selected for each component—from the high-grade rubber compounds in cushioning elements to the specially treated steel in structural brackets—are engineered to withstand extreme temperatures, chemical exposure, and continuous stress cycles without compromising performance or safety.

The modular construction of the FAW Engine Mounting allows for targeted repairs and replacements, providing significant cost advantages over competitive systems that require complete assembly replacement. This design philosophy aligns with FAW’s commitment to delivering practical, economical solutions for commercial vehicle operators without sacrificing quality or performance standards.

Correct installation of FAW Engine Mounting components requires adherence to specific procedures to ensure optimal performance and longevity. Before beginning any installation, technicians should verify that all replacement parts match the specifications outlined in the parts table above. Proper alignment during installation is critical for the FAW Engine Mounting system to function as designed, with even load distribution across all mounting points.

Torque specifications for fasteners within the FAW Engine Mounting system must be strictly followed to prevent both under-tightening, which can lead to component movement and premature wear, and over-tightening, which may damage components or distort mounting points. A calibrated torque wrench should always be used when working with the FAW Engine Mounting fasteners to ensure accuracy.

After installing new FAW Engine Mounting components, a thorough inspection should be conducted to verify proper alignment and secure fastening. Operational testing should include running the engine at various RPM levels while observing for excessive vibration or movement that might indicate installation issues. Following these procedures will ensure that the FAW Engine Mounting system performs optimally throughout its service life.

The FAW Engine Mounting system offers numerous advantages for commercial vehicle operators. Its robust construction ensures reliable performance under the most demanding conditions, while the comprehensive parts breakdown facilitates cost-effective maintenance. The thoughtful engineering of the FAW Engine Mounting translates to tangible benefits including reduced vehicle downtime, lower maintenance costs, and enhanced operational safety.

Another significant advantage of the FAW Engine Mounting design is its compatibility with various service and repair scenarios. The modular approach allows technicians to address specific wear issues without replacing the entire assembly, providing substantial cost savings for fleet maintenance operations. This flexibility, combined with the durability of genuine FAW components, makes the FAW Engine Mounting system an excellent long-term investment for commercial vehicle operators.

The vibration damping characteristics of the FAW Engine Mounting system contribute to overall vehicle refinement, reducing driver fatigue and enhancing the operational experience. By effectively isolating engine vibrations, the system also protects sensitive electronic components and other vehicle systems from excessive stress, potentially extending their service life and reducing overall operating costs.

Our comprehensive resources include detailed technical specifications, installation guides, and maintenance procedures for the complete FAW Engine Mounting system and related components.