The FAW Cylinder Block Assembly is a critical component in the CA3250P66K2L1T1E 6×4 flat-head diesel dump truck, engineered by FAW Jiefang for durability and high performance. This guide provides a detailed parts breakdown, disassembling large structural components and procurement units into the smallest repairable elements. It serves as an essential resource for mechanics and enthusiasts, ensuring efficient maintenance and repair. By exploring each part, users can enhance their understanding of the engine’s core structure, optimize replacement procedures, and extend the vehicle’s lifespan. The FAW Cylinder Block Assembly exemplifies advanced manufacturing, designed to withstand rigorous conditions in construction and transportation applications.

FAW Cylinder Block Assembly

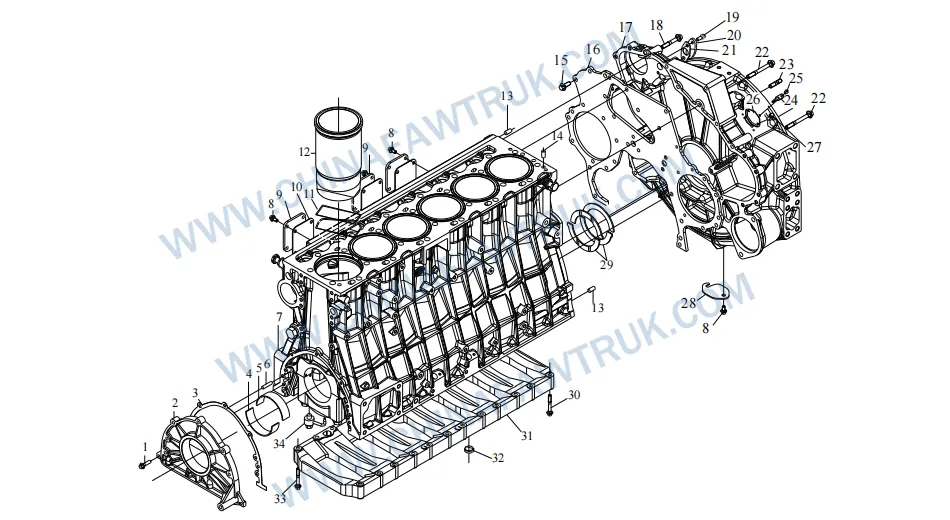

Below is the comprehensive parts table for the FAW Cylinder Block Assembly, listing each component with its part number, name, and quantity. This table helps in identifying and sourcing parts for maintenance, ensuring accuracy in repairs. The FAW Cylinder Block Assembly includes key elements like cylinder sleeves, main bearing shells, and sealing components, all designed for reliability.

This detailed parts list for the FAW Cylinder Block Assembly ensures that every component is accounted for, from bolts and seals to critical structural parts. Proper identification aids in efficient repairs and replacements.

The FAW Cylinder Block Assembly forms the foundation of the engine, housing crucial parts like cylinders, crankshaft, and camshaft. Each element is precision-engineered for the CA3250P66K2L1T1E model, ensuring optimal performance in demanding environments. For instance, the cylinder sleeves are made from high-strength materials to resist wear, while the main bearing shells provide smooth crankshaft operation. This assembly is designed for easy disassembly, allowing mechanics to access repairable units without major overhauls. Regular maintenance of the FAW Cylinder Block Assembly can prevent engine failures and reduce downtime.

In the FAW Cylinder Block Assembly, components like the gear chamber cover and flywheel housing are integral for power transmission. The use of interchangeable parts, such as gaskets and seals, simplifies sourcing and reduces costs. This breakdown highlights the importance of each part in the overall system, emphasizing durability and compatibility. By understanding these details, users can make informed decisions during repairs, ensuring the longevity of their FAW trucks.

Maintaining the FAW Cylinder Block Assembly involves regular inspections and timely replacements. Start by checking for oil leaks around seals and gaskets, as these can indicate wear. Use the parts table to order genuine components, ensuring compatibility. When disassembling, follow a systematic approach: remove bolts in sequence, label parts, and clean surfaces to avoid contamination. The FAW Cylinder Block Assembly is built for repairability, so even minor units like pins and bolts can be replaced individually.

For complex repairs, refer to the FAW Cylinder Block Assembly diagram to locate parts accurately. Common issues include cylinder sleeve erosion or bearing wear, which should be addressed promptly to prevent engine damage. Always use recommended tools and torque specifications during reassembly. This proactive maintenance extends the life of the FAW Cylinder Block Assembly and enhances vehicle reliability. Remember, proper handling of this assembly is key to maximizing the performance of your FAW dump truck.

The FAW Cylinder Block Assembly is a vital part of the CA3250P66K2L1T1E dump truck, designed for robustness and easy maintenance. This guide provides a thorough breakdown, empowering users to perform effective repairs. By utilizing the parts list and maintenance tips, you can ensure your FAW truck operates at peak efficiency. Explore other FAW parts and vehicles to support your transportation needs, and always rely on genuine components for optimal performance.

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.